-

Products

-

3A Tube Fittings

-

Tri-Clamp Fittings

-

Elbows

- EG2C - Clamp 90 Degree Elbow

- EG2FPR - Clamp X Plain BS w/13H Nut 90 Degree Elbow

- EG2FTR - Clamp X Thread BS 90 Degree Elbow

- EG2C31CC - Clamp Reducing 90 Degree Elbow

- EG2K - Clamp 45 Degree Elbow

- EG231FPR - Clamp X Plain BS w/13H Nut 90 Degree Elbow

- EG2C31PR - Clamp X Plain BS Reducing 90 Degree Elbow

- EG2WU - Clamp 180 Degree U Bend

- Tees

- Crosses

- Ferrules

- Adapters

- Caps

- Gaskets

- True Y's and Laterals

-

Reducers

- EG31CC - Clamp Concentric Reducer

- EG32CC - Clamp Eccentric Reducer

- EG31PC - Plain BS X Clamp Concentric Reducer

- EG32PC - Plain BS X Clamp Eccentric Reducer

- EG31CP - Clamp X Plain BS w/13H Nut Concentric Reducer

- EG32CP - Clamp X Plain BS w/13H Nut Eccentric Reducer

- EG31TC - Thread BS X Clamp Concentric Reducer

- EG32TC - Thread BS X Clamp Eccentric Reducer

- EG31CT - Clamp X Thread BS Concentric Reducer

- EG32CT - Clamp X Thread BS Eccentric Reducer

- Clamps

- Schedule 5 & 10

-

Elbows

-

Butt Weld Fittings

-

Elbows

- 2WCL - Weld 90 Degree Elbow Short

- E2S - Weld 90 Degree Elbow with Tangents

- E2C - Weld X Clamp 90 Degree Elbow

- E2F - Weld X Plain BS w/13H Nut 90 Degree Elbow

- E2T - Weld X Thread BS 90 Degree Elbow

- E2WK - Short Weld 45 Degree Elbow

- E2KS - Weld 45 Degree Elbow with Tangents

- E2KC - Weld X Clamp 45 Degree Elbow

- E2KT - Weld X Thread BS 45 Degree Elbow

- E2KP - Weld X Plain BS w/13H Nut 45 Degree Elbow

- E2WU - 180 Degree U-Bends

-

Tees

- E7W- Long Weld Tee

- E7WWW - Weld Tee

- E7WWCS - Weld X Weld X Clamp Short Outlet Tee

- E7WWC - Weld X Weld X Clamp Tee

- E7WWT - Weld X Weld X Thread BS Tee

- E7WCW - Weld X Clamp X Weld Tee

- E7WTW - Weld X Thread BS X Weld Tee

- E7WCC - Weld X Clamp X Clamp Tee

- E7WTT - Weld X Thread BS X Thread BS Tee

- E7CCW - Clamp X Clamp X Weld Tee

- E7TTW - Thread BS X Thread BS X Weld Tee

- Reducing Tees

- Crosses, Stub Ends, Flanges & Caps

- True Y's and Laterals

- Reducers

- Adapters

-

Elbows

-

Bevel Seat & John Perry Fittings

- Elbows

- Tees

- Crosses & Hex Union Nuts

-

Ferrules

- 14A - Plain BS Ferrule Medium

- 14PR - Plain BS Ferrule Short

- 14W - Plain BS Heavy Wall Tank Ferrule

- 14WL - Plain BS Ferrule Long

- 15A - Thread BS Ferrule Medium

- 15TR - Thread BS Ferrule Short

- 15W - Thread BS Heavy Wall Tank Ferrule

- 15WL - Thread BS Ferrule Long

- 14 - Plain BS Recessed Ferrule

- 14R - Plain BS Roll-on Ferrule

- 15 - Thread BS Recessed Ferrule

- 15R - Thread BS Roll-on Ferrule

- Caps

-

Reducers

- 31-14F - Plain BS w/13H Nut Both Ends Concentric Reducer

- 31-15F - Plain BS X Thread BS Concentric Reducer

- 31TT - Thread BS X Thread BS Concentric Reducer

- 31TP - Thread BS X Plain BS w/13H Nut Concentric Reducer

- 32-14F - Plain BS w/13H Nut Both Ends Eccentric Reducer

- 32-15F - Plain BS w/13H Nut X Thread BS Eccentric Reducer

- 32TT - Thread BS X Thread BS Eccentric Reducer

- 32TP - Thread BS X Plain BS w/13H Nut Eccentric Reducer

- Adapters

- John Perry Ferrules, & Caps

-

E-Line & Q-Line Fittings

- Elbows

-

Tees

- E7I - Female E-Line X Female E-line X Female E-Line Tee

- E7AI - Female E-Line X Female E-line X Male E-Line Tee

- E7BI - Male E-Line X Female E-line X Female E-Line Tee

- E7EI - Male E-Line X Male E-line X Female E-Line Tee

- E7HI - Male E-Line X Male E-line X Male E-Line Tee

- E7RI - Female E-Line End Reducing Tee

- E9I - Female E-Line Cross

- Ferrules

- Adapters

- True Y's and Laterals

- Caps

-

Reducers

- E31I-14I - Male E-Line Concentric Reducer

- E31I-14I-15I - Male E-Line X Female E-Line Concentric Reducer

- E31I-15I-14I - Female E-Line X Male E-Line Concentric Reducer

- E31I-15I - Female E-Line Concentric Reducer

- E32I-14I - Male E-Line Eccentric Reducer

- E32I-14I-15I - Male E-Line X Female E-Line Eccentric Reducer

- E32I-15I-14I - Female E-Line X Male E-Line Eccentric Reducer

- E32I-15I - Female E-Line Eccentric Reducer

- Q-Line Fittings

- Gaskets

- Clamps and Gaskets

- Schedule 5 & 10

- Miscellaneous

-

Tri-Clamp Fittings

-

Maxpure BPE Fittings

-

Butt Weld Fittings MaxPure 316L

-

Elbows MaxPure 316L

- TE2KS - BPE AWF 45 Degree Elbow MaxPure 316L

- TE2KC - BPE Clamp X AWF 45 Degree Elbow MaxPure 316L

- TE2S88 - BPE AWF 88 Degree Elbow MaxPure 316L

- TE2C88 - BPE Clamp X AWF 88 Degree Elbow MaxPure 316L

- TE2S - BPE AWF 90 Degree Elbow MaxPure 316L

- TE2C - BPE Clamp X AWF 90 Degree Elbow MaxPure 316L

- TE2S92 - BPE AWF 92 Degree Elbow MaxPure 316L

- TE2C92 - BPE Clamp X AWF 92 Degree Elbow MaxPure 316L

- Tees MaxPure 316L

- Off Angle Tees MaxPure 316L

- Reducing Tees MaxPure 316L

- Instrument Tees MaxPure 316L

- Reducers MaxPure 316L

- Point of Use Elbows MaxPure 316L

- True Y's and Laterals MaxPure 316L

- Crosses MaxPure 316L

- Caps MaxPure 316L

- Adapters and Stub Ends MaxPure 316L

-

Elbows MaxPure 316L

- Tri-Clamp Fittings MaxPure 316L

-

Butt Weld Fittings MaxPure 316L

- Unpolished Tube OD Weld Fittings

-

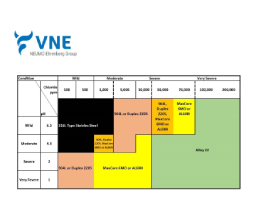

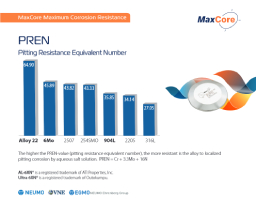

MaxCore BPE Special Alloy Fittings

-

6MO UNS N08367

-

Weld Fittings 6MO UNS N08367

- Adapters and Stub Ends 6MO UNS N08367

-

Elbows 6MO UNS N08367

- TE2C - BPE Clamp X AWF 90 Degree Elbow 6MO UNS N08367

- TE2C88 - BPE Clamp X AWF 88 Degree Elbow 6MO UNS N08367

- TE2C92 - BPE Clamp X AWF 92 Degree Elbow 6MO UNS N08367

- TE2KC - BPE Clamp X AWF 45 Degree Elbow 6MO UNS N08367

- TE2KS - BPE AWF 45 Degree Elbow 6MO UNS N08367

- TE2S - BPE AWF 90 Degree Elbow 6MO UNS N08367

- TE2S88 - BPE AWF 88 Degree Elbow 6MO UNS N08367

- TE2S92 - BPE AWF 92 Degree Elbow 6MO UNS N08367

- Reducers 6MO UNS N08367

- Instrument Tees 6MO UNS N08367

- Reducing Tees 6MO UNS N08367

- Tees 6MO UNS N08367

- Clamp Fittings 6MO UNS N08367

-

Weld Fittings 6MO UNS N08367

-

Alloy 22 UNS N06022

-

Weld Fittings Alloy 22 UNS N06022

- Adapters and Stub Ends Alloy 22 UNS N06022

-

Elbows Alloy 22 UNS N06022

- TE2C88 - BPE Clamp X AWF 88 Degree Elbow Alloy 22 UNS N06022

- TE2C92 - BPE Clamp X AWF 92 Degree Elbow Alloy 22 UNS N06022

- TE2C - BPE Clamp X AWF 90 Degree Elbow Alloy 22 UNS N06022

- TE2KC - BPE Clamp X AWF 45 Degree Elbow Alloy 22 UNS N06022

- TE2KS - BPE AWF 45 Degree Elbow Alloy 22 UNS N06022

- TE2S88 - BPE AWF 88 Degree Elbow Alloy 22 UNS N06022

- TE2S92 - BPE AWF 92 Degree Elbow Alloy 22 UNS N06022

- TE2S - BPE AWF 90 Degree Elbow Alloy 22 UNS N06022

- Reducers Alloy 22 UNS N06022

- Instrument Tees Alloy 22 UNS N06022

- Reducing Tees Alloy 22 UNS N06022

- Tees Alloy 22 UNS N06022

- Clamp Fittings Alloy 22 UNS N06022

-

Weld Fittings Alloy 22 UNS N06022

-

6MO UNS N08367

-

Valves

- Ball Valves

-

Butterfly Valves

-

51 Series Butterfly Valves

-

Manual Valves

- 51C STH - Clamp End Manual Butterfly Valve Stainless Trigger Handle

- 51W STH - Weld End Manual Butterfly Valve Stainless Trigger Handle

- 51C PTH - Clamp End Manual Butterfly Valve Poly Trigger Handle

- 51W PTH - Weld End Manual Butterfly Valve Poly Trigger Handle

- 51C PH - Clamp End Manual Butterfly Valve Pull Handle

- 51W PH - Weld End Manual Butterfly Valve Pull Handle

- Actuated Valves

-

Actuated Valves With Control Top

- 51C VMON-ASI - Clamp End Spring Return Pneumatically Actuated Butterfly Valves With ASI Control Top

- 51W VMON-ASI - Weld End Spring Return Pneumatically Actuated Butterfly Valves With ASI Control Top

- 51C VMON-24V - Clamp End Spring Return Pneumatically Actuated Butterfly Valves With 24V Control Top

- 51W VMON-24V - Weld End Spring Return Pneumatically Actuated Butterfly Valves With 24V Control Top

- 51 Series Valve Components

- 51 Series Actuator Components

-

Manual Valves

-

B Series Butterfly Valves

- Manual Valves

- Actuated Valves

-

Actuated Valves With Control Top

- VMON24CCB - B Series Clamp End Actuated Butterfly Valves With 24VDC Control Top

- VMON24SSB - B Series Weld End Actuated Butterfly Valves With 24VDC Control Top

- VMONASICCB - B Series Clamp End Actuated Butterfly Valves With ASI Control Top

- VMONASISSB - B Series Weld End Actuated Butterfly Valves With ASI Control Top

- B Series Butterfly Valve Components

- B Series Actuated Butterfly Valve Components

-

51 Series Butterfly Valves

-

Check Valves

-

Ball Check Valves

- EG45BY - Clamp End Ball Check Valve

- E45BYWW - Weld End Ball Check Valve

- Ball Check Valve Components

- EG45ABA - Clamp Ball Check Valve w/Air Blow Check Quick connect Type A

- EG45ABB - Clamp Ball Check Valve w/Air Blow Check Hose Barb Type B

- EG45ABC - Clamp Ball Check Valve w/Air Blow Check NPT Type C

- E45WWABA - Weld Ball Check Valve w/Air Blow Check Quick Connect Type A

- E45WWABB - Weld Ball Check Valve w/Air Blow Check Hose Barb Type B

- E45WWABC - Weld Ball Check Valve w/Air Blow Check NPT Type C

- Spring Check Valves

- Air Blow Check Valve

-

Ball Check Valves

- PVE Single Seat Valve

- Tubing

- Specialty Fabrications

-

3A Tube Fittings

- News

- Downloads

- About

- Contact us

- MTR Retrieval

You have no items in your shopping cart.